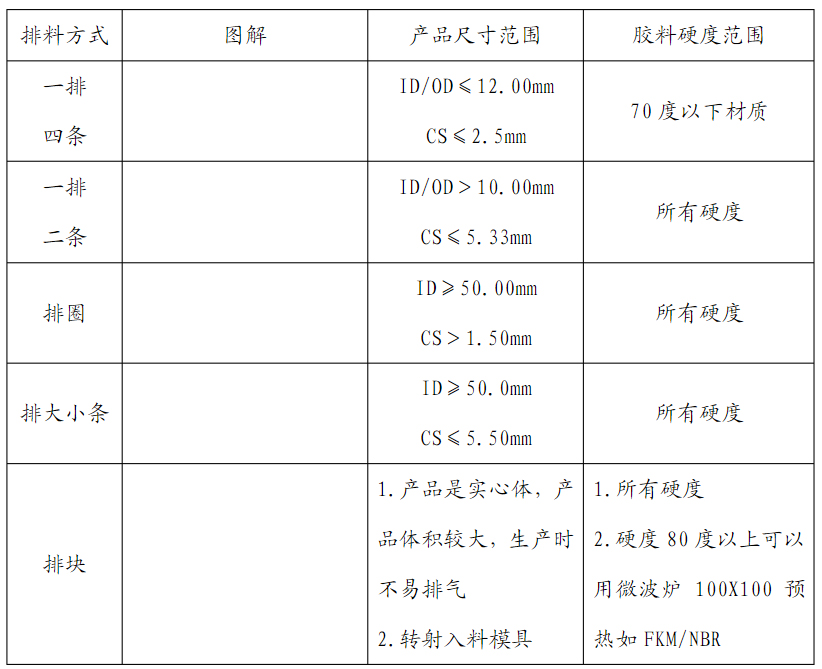

I. product layout

1. The shape, volume and hardness of products are arranged in different ways

Note: the above arrangement can be referred to in general, and other operation modes shall be selected for special mold structure reasons.

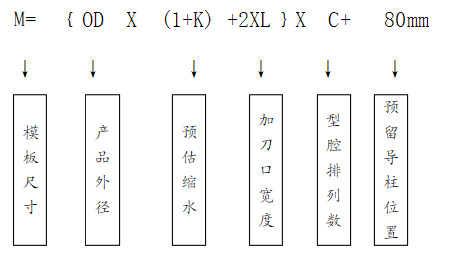

II. Template size setting

1. Template size, mainly refers to the contact size between the mold tool surface and the electric heating plate surface. The larger the pressure surface the mold bears, the higher the pressure

The smaller the product is, the thicker the burr is, and it is easy to be short of materials. On the contrary, the smaller the pressure bearing surface of the mold is, the greater the bearing pressure is

The thinner the burr is, the less material is needed, and the mold temperature is more uniform.

2. The size of the formwork is set according to the required size of the product and the number of holes quoted. Generally, the cavity surface of the mold is designed as

Square, so that the mold pressure is even, mold temperature is more even.

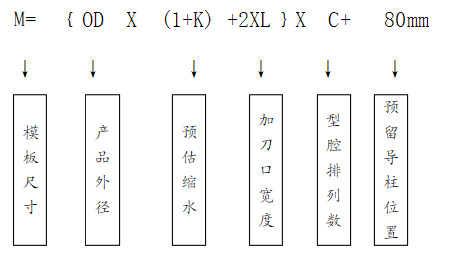

Calculation formula

For example: the estimated shrinkage of the model with an outer diameter of 15mm is 3%, and the blade width is 1.5mm. The cavity arrangement number is 10 holes

M= { 15X(1+0. 03) +2X1. 5 } X10+80=264. 5mm

The size of 260mmx260mm can be selected as the formwork. If the calculated value is 280mm-300mm, the formwork of 310mmx31mm can be selected.

The above is only for 0-ring and ordinary gasket products. If the template size is modeled by other irregular models, it needs to be reevaluated.

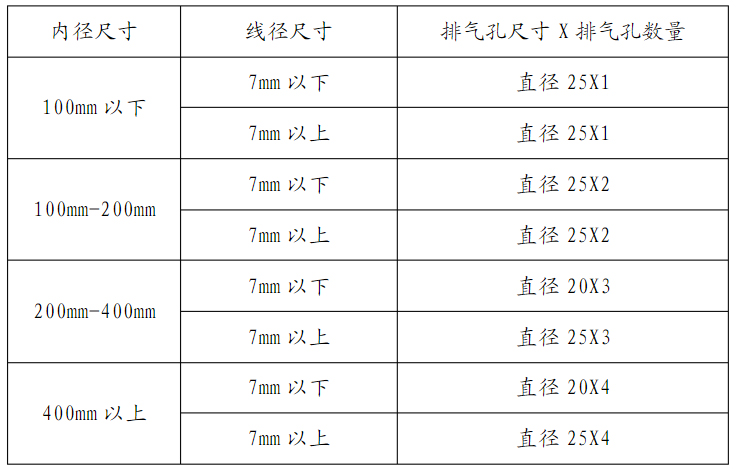

III. setting of exhaust tank / vent

1. The setting of exhaust slot varies according to the shape and height requirements of the product. Width can be set for general 0-ring products

3.0 x depth 0.30 mm-0.50 mm, the product thickness can be adjusted appropriately.

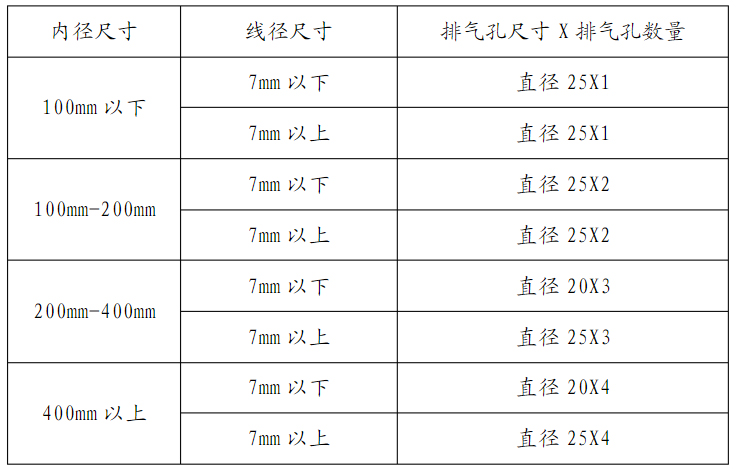

2. The setting of vent hole is mainly different according to the inner diameter and wire diameter requirements of the product, generally 0-ring and other class E products

For products with large inner diameter, the exhaust hole shall be located close to the mold cavity, with a distance of 50-70mm, which is conducive to exhaust.